Vision-guided depalletizing on Fanuc Industrial Robot: Inbolt’s Collaboration with Stellantis

Vision-guided depalletizing on FANUC

Inbolt is now compatible with Fanuc robots, and on industrial robots.

GuideNOW can now depalletize items with unparalleled speed and efficiency; our 3D camera system is seamlessly integrated onto the end effector, allowing GuideNOW to locate the part with precision and flexibility.

Regardless of the part’s positioning, GuideNOW can thus ensure optimized performance.

At Inbolt, our mission is to streamline industrial automation in a simple and accessible way. Easy to implement and easy to program, we make automation straightforward.

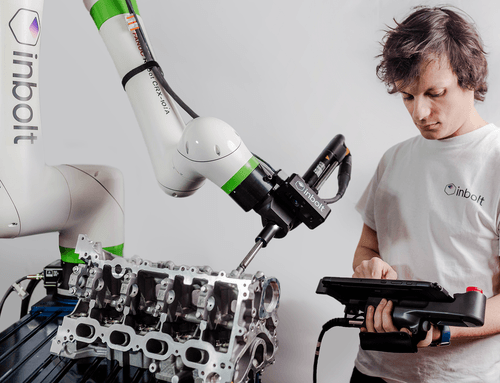

Our recent collaboration with Stellantis in Hungary exemplifies how real-time guidance and robotic precision can transform manufacturing processes. We enhanced their structured bin picking fixed station process for cylinder head depalletizing and loading on the line with our robot guidance vision system.

This case study highlights the integration of our GuideNOW system into the automotive sector.

The Challenge

Stellantis aimed to improve the efficiency of their cylinder head processing line in Hungary by streamlining the loading and unloading process—ensuring precision, speed, and minimal downtime. This involved handling machined cylinder heads from the machining line, transferring them through various stages, and preparing them for the main assembly line. The process required meticulous coordination, quick turnaround times, and reliable robotic assistance in a non-repeatable setting.

The Solution

Inbolt provided a comprehensive solution by integrating GuideNOW Real Time with Fanuc robots into Stellantis’ workflow.

Utilizing our 3D camera and GuideNOW application, the robots achieve precise positioning, reducing errors and increasing output.

Machined cylinder heads are delivered via Automated Forklift Taggers and placed on a turntable. The turntable rotates to position the pallets for a Fanuc robot, which uses a camera for precise picking and placing of the cylinder heads onto a conveyor for pre-assembly. At the final pre-assembly station, the robot moves the cylinder heads to pallets at the unloading station, and Automated Guided Vehicles transport them to the main assembly line.

Impact

The implementation of Inbolt’s robotic solution at this Stellantis factory is steadily improving the efficiency and accuracy of the cylinder head processing line.

We are proud to have partnered with Stellantis in Hungary, bringing startup innovation quality to their manufacturing process.

Our expertise in real-time guidance and robotics, combined with Fanuc’s reliable technology and Stellantis’ knowledge of automation has delivered a solution that meets the high demands of the automotive industry.

For more information about our solutions and how we can transform your manufacturing processes, visit Inbolt’s website.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Reliable 3D Tracking in Any Lighting Condition

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation