Thinking Machines: Why Robots Rely on Artificial Intelligence

Artificial intelligence (AI) has been around since 1956, when it was coined by John McCarthy during a conference. Since then, AI has had a slow but steady coming to, with 2023 quickly becoming the year of AI.Today, we are taking a step back to explain what AI is, and why it is relevant to automation in the manufacturing industry.

Artificial intelligence (AI) has been around since 1956, when it was coined by John McCarthy during a conference. Since then, AI has had a slow but steady coming to, with 2023 quickly becoming the year of AI.

Today, we are taking a step back to explain what AI is, and why it is relevant to automation in the manufacturing industry.

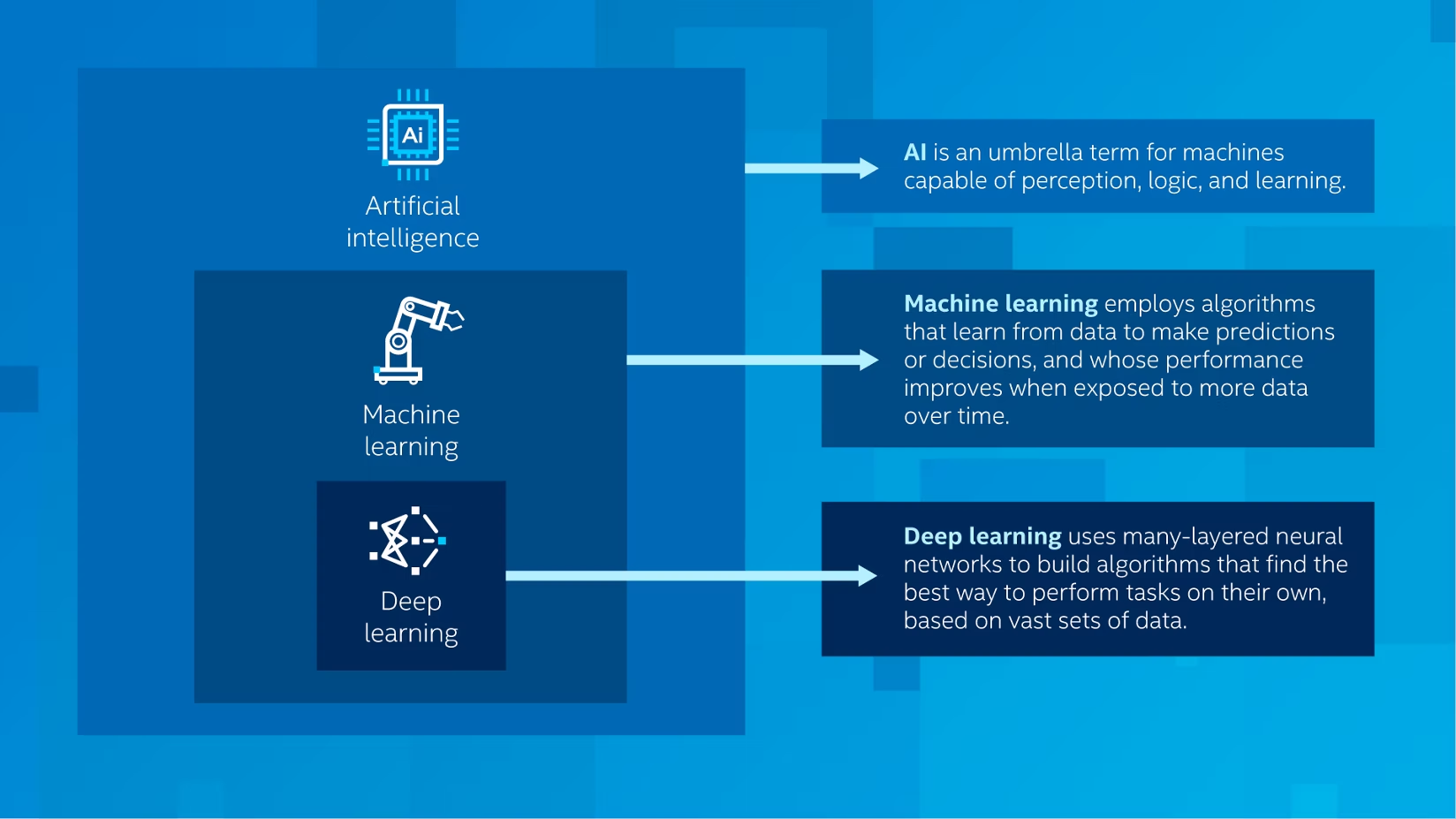

What is AI?

AI contains several branches: Artificial Intelligence (AI), Machine Learning (ML) and Deep Learning (DL). These are all interconnected parts of computer science, but while AI encompasses the entirety of the branch, ML and DL are subsets of AI, with the former dealing with the study of algorithms and statistical models relying on patterns and inference, and the latter handling neural networks with many layers that learn progressively more complex features of the data (like processing images and text).

All branches of AI rely on one main idea: the mimicking of human intelligence, using rules, logic, or a knowledge-based approach. ML goes further by learning patterns from data, and DL learns through an artificial neural network that mimics the human brain. All branches of AI have something in common: their ability to improve over time through “learning” experiences.

Robotics without AI

Robotics without AI refers to robots that operate based on predefined rules and algorithms, without the ability to learn from their experiences or adapt to new situations autonomously.

In practice, it’s possible to have robots with or without AI.

Without, robots are programmed to perform specific tasks, and their actions are determined by explicit instructions provided by human programmers. They can’t make decisions beyond their programming. For example, with industrial robots in manufacturing, they’ll be able to perform repetitive tasks like welding, painting, or assembly with high precision and speed, but won’t be able to adapt to changes in their environment or tasks without reprogramming.

Robotics with AI

Robotics with AI refers to robots that can learn, adapt, and make decisions autonomously. AI enables them to process information from their environment, learn from experiences, and perform complex tasks with a level of ‘intelligence’.

The key difference is the level of autonomy and adaptability.

AI lets robots handle unpredictability and complexity in their tasks and environments, which is not possible with traditional robotics.

What AI means for robotics

While AI started almost 70 years ago, its application in the manufacturing industry is still relatively new.

Within robotics, here are the ones that are the most used:

- Object recognition (essential for autonomous navigation and manipulation)

- Motion planning (finding a collision-free path for a robot to move from one point to another)

- Control (involves regulating the movement of robots)

- Localization (the process of determining the position of a robot in its environment)

- Object Detection (detecting and localizing objects in an image)

So while AI has been around for quite a while, it has only recently started to be successfully included and linked to other systems. In the robotics and manufacturing industry in particular, this new development has started a paradigm-shifting experience, whereby AI has been bleeding into all forms of technologies, with more or less success.

Within the manufacturing industry, AI has been particularly good at enabling better perception, adaptiveness and imbuing capability to the robotic systems.

The end goal of AI is to give systems that do not have any life form a level of decision-making capabilities. This is done through four main angles:

- Vision: visualize and detect patterns that systems have never encountered, and work on these patterns with accuracy.

- Grasping: provide direction to the robots to guide it on to the best position to grasp an object.

- Motion Control: enable obstacle awareness and dynamic interaction.

- Data: enable correct data to be shared in order to make it successful.

AI in manufacturing robotics

The idea of AI, thus far, has been to equip system with a high level of information in order to help systems make decision on their own—if only partly.

Within the manufacturing industry, AI robotics has evolved to be able integrated into:

- High-precision assembly line

- Collaborative robots that work beside humans

- AI-driven computer vision to enable real-time course correction, like Inbolt’s guideNOW system

- Robots with advanced cognitive abilities and adaptability to new scenarios

- Robots’ increased autonomy

- Hyper-specific task optimization for efficiency.

The automotive industry in particular is a very highly automatized industry, and automakers are actively researching more ways to introduce automation in their industries, from assembly to welding, parts removal, parts transfer, machine tending, etc. It is estimated that the automation market size in the automotive industry could increase by USD 1.95 billion between 2021 and 2026.

The automotive industry is a great fit for automation: it allows around-the-clock operation, cutting down costs and mistakes – a big deal when equipment can cost thousands. Automation also ups accuracy and reliability, which are key for car makers.

The automotive industry (and, more broadly, the manufacturing industry) has been using robotic intelligence for more than 50 years. The only change from then to now is the advancement of AI and ML in this branch, which has been a drastic one, allowing for accurate vision to locate items, assembling machine devices like motors, and unstructured bin picking amongst other things.

Unstructured bin picking is worth mentioning as it is an application that has truly been driving the adoption of AI for robot guidance in recent years. For years, it represented a significant challenge in robotics and automation due to its inherent complexity and variabilities.

Modern solutions like Inbolt’s GuideNOW system is already able to work on semi-structured bin-picking, whereby the robot arm can identify and handle objects in a bin that are randomly arranged. With its continuous update, GuideNOW allows the robot to see and understand the scene in order to make accurate picking decisions.

And while it is difficult to predict specific trends, factors are currently in favor or AI in robotics, and it is expected that AI could create 12 million more jobs than it terminates by 2025.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Why the future of automation is being written by the automotive industry

Reliable 3D Tracking in Any Lighting Condition

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?