How to Automate Bin-picking

In an era marked by rapid technological advancements and growing labor shortages, the demand for automation has been escalating for years now. In the United States alone, half a million manufacturing positions lie vacant. Faced with such statistics, the race to perfect automated bin-picking technology has never been more urgent.

About 38% of the US manufacturing labor force is employed in transferring components between bins and machines, a role that appears prime for automation. In theory.

The reality is far more intricate.

Definition

Bin-picking describes a process that can be found in a large diversity of industries: Manufacturing, logistics industry, fulfillment centers, food processing plants, bin picking can be found in almost every industry, whether it is picking machined parts, parcels, SKUs or even poultry, in boxes.

However, not all bin picking environments are the same:

Unstructured vs. Structured

- Structured environments, in which parts are clearly separated into distinct compartments, have long been associated with organizational clarity. It is the Graal of all environments, but difficult to achieve and complex to maintain.

- Unstructured scenarios present a unique challenge. With overlapping parts and spatial randomness, a different solution framework is needed to effectively navigate this type of environment. This means approaching problems with a more flexible and adaptable mindset, one that can quickly pivot and adjust to changing circumstances. It also means being able to identify patterns and relationships that may not be immediately apparent, and using these insights to inform decision-making.

When it comes to robotics and manufacturing, structured environments are what everyone wishes for, while the second environment is what tends to be the norm.

Diversity vs. Single Reference

In a warehouse or distribution center, the decision to use either diverse or uniform bins can have a significant impact on the efficiency of operations.

With diverse bins, multiple references of parts or products can be housed in the same bin, which presents a challenge for the system to recognize, sort, and pick the correct item. This can result in longer processing times and a higher probability of errors occurring.

On the other hand, uniform bins simplify the storage process by housing only one type of product, which enables straightforward picking strategies and reduces the likelihood of errors. However, this method may not be suitable for facilities that require the storage of a large variety of products.

With the ever-growing rise of low volume, high mix manufacturing trends, uniform bins are becoming increasingly problematic as they no longer fit with the manufacturing industry’s current needs.

Known or Unknown Products

Bin picking solutions involve the use of pre-trained systems that are able to recognize and pick known products, typically through the use of 3D models or AI algorithms.

This approach is effective when dealing with products that are well established and can be easily identified by the system. However, not all products are always known beforehand, which is when it gets tricky and requires a more dynamic approach.

In such cases, Deep Learning becomes a valuable tool for on-the-fly adaptability, whereby the system can learn to recognize and pick items that were previously unknown, expanding the range of products that can be handled.

How to Automate Bin-Picking?

- Reliable & robust vision system: to segment parts if cluttered, identify their position & orientation and send their coordinates to the robot control software. In some cases the vision system should also recognize the product to pick thanks to AI. Bin picking is one of the most developed applications for 3D sensors which have been real enablers of the automation of this process.

- Picking strategy definition: most of the time picking points are defined during programming and training of the vision system for part recognition.

- Path planning algorithm: generate a picking trajectory according to the product position & orientation. This involves quite deep integration with the different robot brands, but now most of the robot brands are developing their own native bin picking capability.

- Collision avoidance capability: the generated picking trajectory needs to avoid obstacles such as the bin sides and manage “extreme use cases” such as products placed in the corners of the box.

- Proper gripper: the one-suits-all theory in the industry is hard to prove. In many cases a custom gripper has to be designed to be able to properly pick the different products in the bin. Also grippers themselves could be damaging products due to collision, this is why we sometimes see long suction grippers that avoid damaging the parts but cannot lift heavy parts.

- Additional capabilities: shaking the bin to avoid parts in the corners, adding a flexible feeding system to declutter small parts, etc. All ideas are good to take when trying to fully empty a bin.

However, not one solution suits all in bin picking, and a careful balance of various components to achieve success is often required.

Bin-Picking Challenges

Although there have been advancements in technology, the quest for 100% bin emptying and handling extreme cases like interlocked parts continues to challenge the industry.

However, there are some interesting developments in the industry that are worth mentioning, as advancements continue to shine through—be it Zivid’s game-changing 3D sensors, Soft Robotics’ specialized grippers for the food industry, or inbolt’s advanced localization algorithms.

While bin picking has the potential to revolutionize manufacturing and logistics operations, it is still a heavy investment that requires the integration of many components, making it a complex operation.

Additionally, it is worth noting that bin picking systems can be slower than human operators due to the heavy processing required by vision sensors.

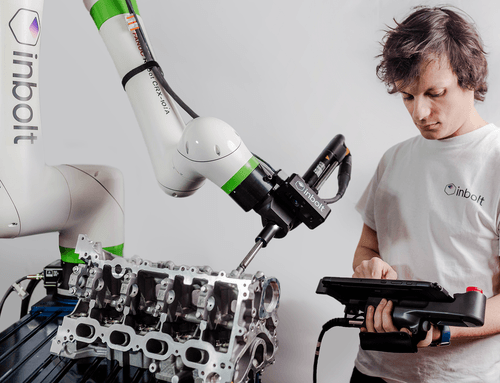

However, our GuideNOW technology offers a solution to some of these challenges. By localizing the position and orientation of a part in real-time—based on its 3D model—we eliminate the need for extensive training and expertise in computer vision. Robotized bin picking can be made easier and more efficient, and our technology represents a significant step forward in that direction.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Reliable 3D Tracking in Any Lighting Condition

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation