inbolt Collaborates Successfully with Stellantis for Automating Tightening Operations on Moving Assembly Lines.

INBOLT and STELLANTIS innovation teams for Manufacturing, based in Vélizy, France, share the successful results of their collaboration regarding the automation of a tightening operation on a moving assembly line.

Automation of assembly operations on continuous moving lines, as often found in the automotive industry, is notoriously difficult.

The intrinsic lack of intelligence from robots makes it impossible for them to adapt to unstructured environments such as moving cars on a line. In the most recent years, to automate such lines, industrials and system integrators have relied on a complex combination of sensors (encoders, presence detectors, 2D vision systems) to automate such lines.

However this proves expensive not only in terms of material but also integration cost, hence only the newest of lines being equipped with such systems.

On the existing continuous lines, manual assembly remains the norm due to the extremely high investments required to retrofit into robotized lines. But with the labour shortage creeping up in most developed countries, the need to preserve factories or even reindustrialize Western Europe, it is now key to find easy to set-up and efficient solutions to automate moving assembly lines.

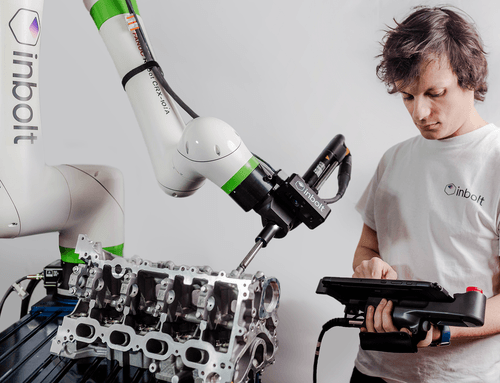

inbolt develops a real-time robot guidance solution, GuideNOW. The GuideNOW system enables smarter industrial robots thanks to adaptive real-time robot guidance based on AI and 3D vision. Its AI-powered system can quickly process large amounts of 3D data and determine the position and orientation of a workpiece. The technology then adapts the robot’s trajectory in real-time.

The Stellantis team showed interest in GuideNOW to automate moving lines and identified a use case to test out the solution. The use case comes from the Trnava assembly plant in Slovakia and consists of performing a tightening sequence of 6 bolts onto a moving engine.

inbolt demonstrated that GuideNOW’s core technology is able to track the position and orientation of the engine in real-time by comparing its CAD model to the 3D data sent by a 3D camera mounted on the robot. GuideNOW then adapts the robot’s programmed trajectory to the position of the engine. The tightening tool used is from Atlas Copco and enables more reach in the tightening trajectory. inbolt showed a 1mm accuracy of the solution, thus guaranteeing the proper fitting of the screwdriver onto the bolts.

The test on Stellantis use case was positive and validated the maturity of the technology for tests in production.

Automate operations in a moving line with reliability is a challenge on which we didn’t find satisfying solutions so far. inbolt proposal is very impressive, and we particularly appreciate the ease of programming, in less that 30 minutes, that allows great flexibility. We now see many opportunities of deployment of GuideNOW solutions on our assembly lines.

Mario Pinto Ferreira

Manufacturing & Supply Chain, Collaborative Robotics Specialist STELLANTIS

About STELLANTIS

STELLANTIS is one of the world’s leading automakers and a mobility provider. Its storied and iconic brands embody the passion of their visionary founders and today’s customers in their innovative products and services, including Abarth, Alfa Romeo, Chrysler, Citroën, Dodge, DS Automobiles, Fiat, Jeep®, Lancia, Maserati, Opel, Peugeot, Ram, Vauxhall, Free2move and Leasys. Powered by our diversity, we lead the way the world moves – aspiring to become the greatest sustainable mobility tech company, not the biggest, while creating added value for all stakeholders as well as the communities in which it operates.

For more information, visit www.stellantis.com.

About inbolt

inbolt is a Paris-based company developing a 3D vision-based robot arm guidance system. The system, called GuideNOW, makes it easy to automate complex operations in unconstrained environments. The solution enhances production line flexibility by eliminating part indexing constraints and improves line productivity as GuideNOW operates in real time. GuideNOW is powered by a breakthrough real-time part localisation AI that identifies the position and orientation of a part under 80 ms based on 3D data. Our customers include some of the world’s biggest automotive OEMs.

For more information, visit www.inbolt.com.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Reliable 3D Tracking in Any Lighting Condition

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation