Stellantis automates semi-structured depalletizing with GuideNOW

Stellantis automated cylinder head depalletizing using FANUC robots and GuideNOW Real-time, overcoming challenges of uneven parts and non-repeatable AMR stops.

Customer: Stellantis

Location: Szentgotthárd, Hungary

Return on Investment: 12 months

Challenge

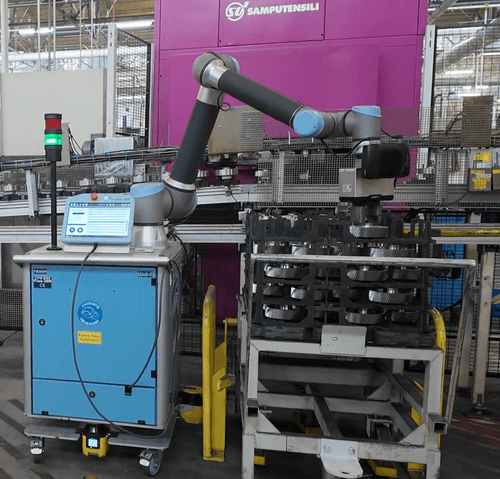

Stellantis aimed to automate the task of picking cylinder heads from pallets and loading them onto the production line. However, the process presented two key challenges:

- The Autonomous Mobile Robot (AMR) delivering the pallets to the station had a non-repeatable stopping position.

- The cylinder heads were laid unevenly on flat surfaces, making their positions unpredictable.

Solution

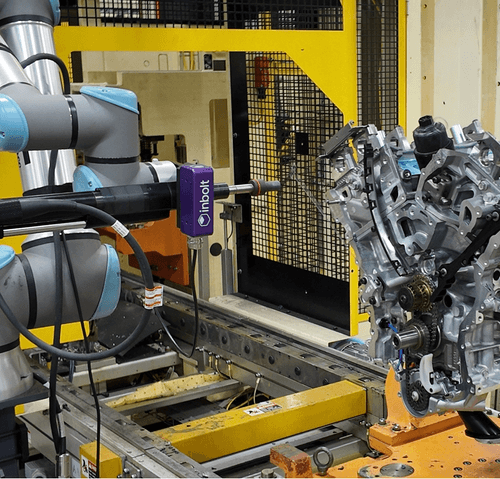

GuideNOW Real-time was mounted directly onto the End of Arm Tooling (EOAT) of a FANUC robot. With its high-precision tracking capabilities, GuideNOW individually locates each cylinder head, realigns the robot’s trajectory, and ensures accurate pick-and-place operations onto the production line. This solution eliminated the need to upgrade the dunnage system, significantly reducing the total cost of automating the station.

Benefits

- Cost-Efficient Automation: No changes to the production environment, minimizing automation costs.

- Ease of Use: Seamless integration with FANUC robots allows users with FANUC expertise to easily operate GuideNOW.

“The way GuideNOW is integrated with FANUC is genius!” — OPEL SZENTGOTTHÁRD, Kaizen Leader.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

30% Cycle Time Reduction in Automotive Pick & Place

Stellantis Reduces Tightening Rejects by 90.5% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis Automates Small Parts Pick and Place

Beko Automates Stones Picking from Bin & Precise Placing

Stellantis automates ferro-alloy leveling and filter insertion inside molds